Air Blaster Installation

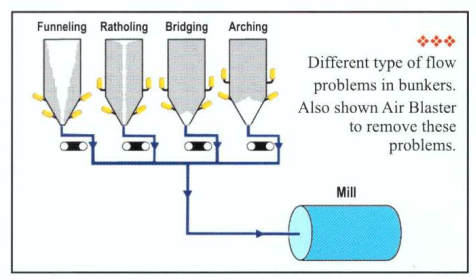

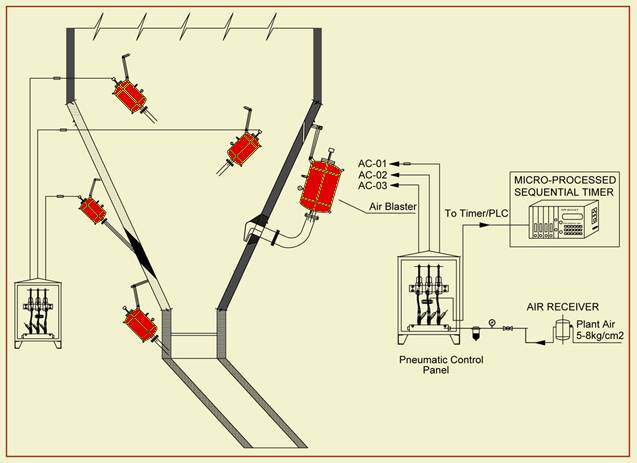

Air Blaster is very effective and economical method of removing jamming in Bunkers, moke Chambers, Kiln Inlet, Coolers, Chutes, Hoppers and Silos etc. and it ensures smooth and continuous flow of materials. It can be installed at any place and its operation is very simple. Even an unskilled worker can operate it with full satisfaction. It works on compressed air 5-7Kgf/cm² which is delivered through pipe lines. Generally plant air is adequate. Incase when plant air is not available at the site, small compress or can be installed as the requirement for operation of Air Blaster is not much. It is operated when ever jamming takes place. By installing this equipment’s, hazardous manual pocking with rod scan be avoided. The cost of installing Air Blasters is quickly recovered through the increased efficiency and reduces down time from the creation of free material flow. EVEN A SINGLE PREVENTED ACCIDENT CAN PAY FOR A COMPLETE INSTALLATION Operating Sequence of Air Blasters should be maintained from TOP to BOTTOM in case of Pre-heater Riser Duct.

Operating Sequence of Air Blasters should be maintained from BOTTOM to TOP in case of Hopper, Bunker, Chute, Cyclone etc.

Air Blasters installed for removing coating in Cyclone-Riser Duct Bend.

Air Blasters installed for removing coating in Grate Cooler.

Air Blasters installed for removing coating in Pre-Heater Inlet Chamber (Duct).

Co-generation from D.G. Sets.

Products Range

| MODEL | DISCHARGE | TANK CAP (LITERS) | FAD AT(7kg/cm2) (in liters) |

APPLICATION |

| AB-05-020 | 050mm | 20 | 140 | Chutes, Small Section |

| AB-10-050 | 100mm | 50 | 350 |

Chutes, Feed Pipes |

| AB-10-070 | 100mm | 70 | 490 | Chutes, Feed Pipes, Cyclone |

| AB-10-100 | 100mm | 100 | 700 | Feed Pipe, Cyclone & Riser Duct |

| AB-10-150 | 100mm | 150 | 1050 | Cyclone, Riser Duct, Cooler, Hopper |

| AB-10-300 | 100mm | 300 | 2100 | Cooler, Hoppers, Bunkers, Silos |

| AB-15-150 | 150mm | 150 | 1050 | Cooler, Hoppers, Bunkers, Silos |

| AB-15-300 | 150mm | 300 | 2100 | Cooler, Hoppers, Bunkers, Silos |